Why use compression seal fitting?

Compression seal fitting from Conax – saves time and money.

What are Compression seal fittings?

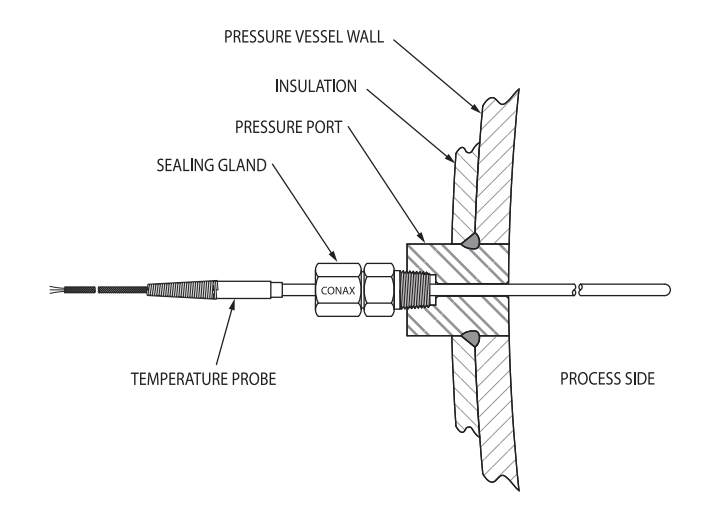

A compression seal fitting is a type of mechanical fitting used to create a hermetic (airtight and watertight) seal where wires, tubes, or probes (such as thermocouples or RTDs) pass through a pressure boundary — such as a wall, vessel, or enclosure.

Key Features:

-

Compression-based sealing: Uses a compression force to deform sealing materials (like soft metal ferrules or elastomeric components) to form a tight seal around the inserted component (e.g., a sensor probe).

-

Pressure resistance: Can handle high pressures, often used in vacuum systems or pressurized environments.

-

Leak-tight: Designed to prevent leaks of gases or liquids.

-

Cable/probe anchoring: Also holds the inserted component securely in place.

Common Applications:

Common Applications:

Sealing thermocouples or RTDs in process pipes or vessels.

-

Passing instrumentation wiring through vacuum chambers or autoclaves.

-

Electrical feedthroughs in sealed environments.

-

Cryogenic systems, nuclear reactors, and high-temperature kilns.

Types of Compression Seal Fittings:

-

Single-ended: Seal around one wire or probe.

-

Multiple lead: Seal around multiple conductors.

-

Electrical or Instrumentation Seals: Allow signals or power to pass while maintaining the seal.

-

Weldable or Threaded Body Types: Depending on how they’re mounted to equipment.

Construction Materials:

-

Body: Stainless steel, Inconel, or other corrosion-resistant metals.

-

Sealing material: Glass (for electrical seals), Teflon, epoxy, or graphite, depending on temperature and pressure requirements.

Here are various Conax compression seal fittings, including multi‑hole metal (MHM), multi‑hole ceramic (MHC), split (PGS), and mid‑lock (MK) styles:

-

Multi‑Hole Metal Fitting (MHM) – stainless steel body sealing 1+ elements with soft sealant, for gas or liquid, vacuum to 10,000 PSI, up to 870 °C

-

Multi‑Hole Ceramic Fitting (MHC) – similar to MHM but uses ceramic insulation between holes Split Compression Fitting (PGS) – split‑seal design allowing easy disassembly when probe diameter changes; seals one element, same temperature/pressure range

-

Metal Ferrule Mid‑Lock Fitting (MK) – metal‑to‑metal seal with stainless ferrule, re‑openable, ideal for high‑vibration, vacuum–10,000 PSI, up to 870 °C

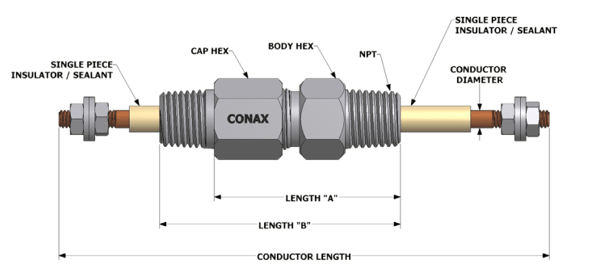

🔧 What You’re Seeing

These are mechanical compression seal fittings — devices that clamp down (compress) on sealant material (soft or metal ferrule) inside a threaded body to create a hermetic seal for probes, tubes, wires, or even fiber optics

They’re used extensively across industries—like autoclaves, pressure vessels, instrumentation feedthroughs, vacuum systems, and reactors—where a leak-tight seal and high pressure/temperature resistance are essential

Quick Summary

Here are various Conax compression seal fittings, including multi‑hole metal (MHM), multi‑hole ceramic (MHC), split (PGS), and mid‑lock (MK) styles:

-

Multi‑Hole Metal Fitting (MHM) – stainless steel body sealing 1+ elements with soft sealant, for gas or liquid, vacuum to 10,000 PSI, up to 870 °C

-

Multi‑Hole Ceramic Fitting (MHC) – similar to MHM but uses ceramic insulation between holes

-

Split Compression Fitting (PGS) – split‑seal design allowing easy disassembly when probe diameter changes; seals one element, same temperature/pressure range

-

Metal Ferrule Mid‑Lock Fitting (MK) – metal‑to‑metal seal with stainless ferrule, re‑openable, ideal for high‑vibration, vacuum–10,000 PSI, up to 870 °C

Example:

A thermocouple is inserted into a pressure vessel. A compression seal fitting is used where the thermocouple wire exits the vessel, ensuring no gas or liquid leaks out and the probe is held securely in place.

Pyrosales can design Custom Seal Fitting Solution.

Example for Solar Power Application.

At Pyrosales, we are proud to partner with Conax Technologies to deliver custom-designed and precision-manufactured seal fittings that enhance the performance and safety of your temperature measurement systems.

A client in the solar power industry recently approached us with a unique challenge. Their application involved introducing thermocouple wires through a high vacuum boundary in a photovoltaic (PV) thin-film coating process. In addition to maintaining vacuum integrity, they sought to reduce electrical noise in the external wiring of their process chamber.

To meet these requirements, our team designed a custom multi-hole compression seal fitting with an integrated flange. This bespoke assembly provided a reliable seal around the thermocouple wires and ensured a secure connection to the customer’s process chamber. Furthermore, a shielding solution was implemented over the bundled wires running from the fitting to the termination box. Within the termination box, a drain wire was connected to the shielding, ensuring proper grounding and significantly minimizing electrical interference.

This custom solution offers several long-term advantages:

- Cost Efficiency: The seal fitting can be rebuilt with new wires as they wear out, eliminating the need to replace the entire assembly.

- Noise Reduction: The addition of shielding effectively reduces electrical noise, enhancing the accuracy of temperature readings.

- Improved Maintenance: The design allows for easy replacement and maintenance, minimizing downtime and operational disruptions.

Pyrosales offers an extensive range of Conax Technologies seal fittings for pressure and vacuum applications, designed to carry sensors, probes, electrodes, wires, and other elements across a broad spectrum of industries. Each solution is tailored to meet the specific needs of the application, ensuring reliability and performance in the most demanding environments.

Common Applications:

Common Applications: