How to Choose the Right Thermocouple

Why Accurate Temperature Measurement Matters.

Inaccurate or unstable temperature measurement can result in:

- Reduced product quality

- Increased energy consumption

- Accelerated equipment wear

- Safety risks to personnel

- Non-compliance with industry standards

For this reason, selecting the correct temperature sensor is not simply a purchasing decision — it is a process engineering decision that directly impacts operational performance.

Among the available temperature sensing technologies, thermocouples remain one of the most widely used solutions in industrial environments. Their durability, versatility, and ability to measure extreme temperatures make them indispensable across a broad range of applications.

Pyrosales, as a long-established Australian manufacturer and specialist in temperature measurement, has decades of experience designing and supplying thermocouples tailored to demanding industrial conditions. This guide draws on that practical expertise to explain how to select the right thermocouple for your application.

Overview of Industrial Temperature Sensors

Before focusing exclusively on thermocouples, it is important to understand where they sit within the broader landscape of temperature measurement technologies.

The most commonly used industrial temperature sensors include:

Each technology has strengths and limitations, and the correct choice depends on the application environment, required accuracy, response time, and operating temperature range.

Thermocouples

Key advantages of thermocouples include:

- Extremely wide temperature measurement range

- Fast response times

- Mechanical robustness

- Resistance to shock and vibration

- Cost-effective design

These characteristics make thermocouples ideal for harsh industrial environments where other sensors may fail.

Resistance Temperature Detectors (RTDs)

Advantages of RTDs include:

- High accuracy

- Excellent repeatability

- Long-term stability

However, RTDs are generally limited to lower temperature ranges and are more sensitive to mechanical damage than thermocouples.

Choosing Between Thermocouples and RTDs

As a general rule:

- Thermocouples are preferred for high temperatures, fast response, and rugged environments.

- RTDs are preferred for lower temperatures where accuracy and stability are critical.

Pyrosales supports both technologies, but thermocouples remain the dominant choice for heavy industrial and high-temperature applications.

What Is a Thermocouple?

A thermocouple consists of two dissimilar metallic conductors joined at one end to form a sensing junction. When the junction is exposed to heat, it generates a voltage proportional to the temperature difference between the sensing junction and the reference junction.

This voltage is measured and converted into a temperature value by an instrument such as:

- Temperature controllers

- Transmitters

- PLC input modules

- Handheld indicators

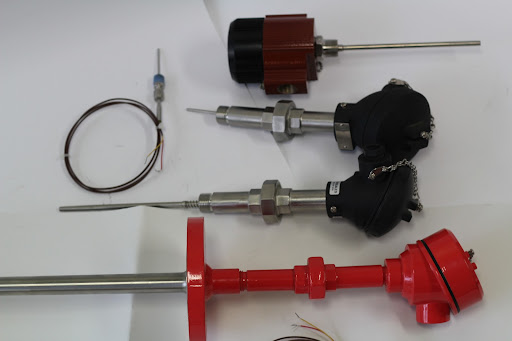

Basic Components of a Thermocouple

A typical industrial thermocouple assembly includes:

- Thermocouple wires (specific alloy combinations)

- Measuring junction

- Insulation

- Protective sheath

- Process connection or fitting

- Extension cable and connectors

Each component plays a critical role in the overall performance, accuracy, and durability of the sensor.

Why Thermocouples Are Widely Used in Industry.

Thermocouples are used extensively across industries due to their ability to operate reliably under conditions that would quickly degrade other sensors.

Wide Temperature Capability.

Depending on the thermocouple type, measurement ranges can extend from below -200 °C to well above 1,600 °C. Certain noble-metal thermocouples can tolerate even higher temperatures under controlled conditions.

This makes thermocouples suitable for applications such as:

- Furnaces and kilns

- Boilers and combustion systems

- Heat treatment processes

- Molten metal environments

- Glass manufacturing

Mechanical Strength and Durability

Industrial thermocouples are often exposed to:

- Vibration

- Mechanical shock

- Abrasion

- Thermal cycling

With appropriate sheath materials and construction, thermocouples can withstand these conditions far better than many alternative sensor types.

Fast Thermal Response.

Thermocouples respond quickly to temperature changes, particularly when designed with grounded or exposed junctions. This is critical in processes where rapid temperature fluctuations must be detected and controlled.

Cost-Effectiveness

Compared to RTDs and other high-accuracy sensors, thermocouples are relatively economical, particularly when high temperatures or multiple measurement points are required.

Understanding Thermocouple Types.

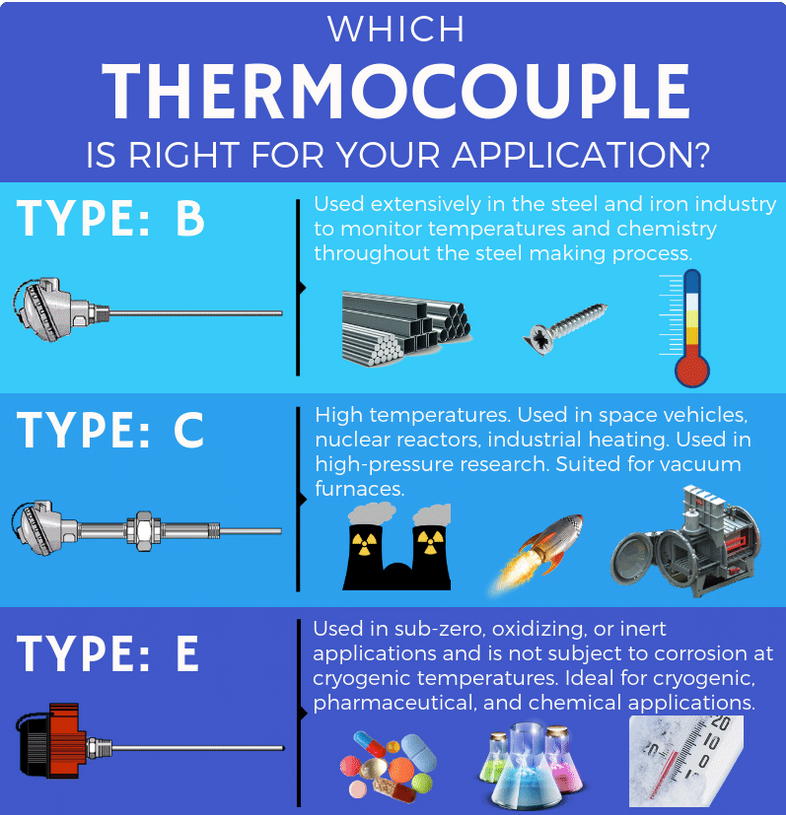

Common thermocouple types include:

- Type K

- Type J

- Type T

- Type E

- Type N

- Type R, S, and B (noble metal types)

Type K Thermocouples

Type K thermocouples are among the most widely used in industrial environments.

Characteristics:

- Nickel-Chromium / Nickel-Aluminium alloy

- Wide temperature range

- Good oxidation resistance

- Cost-effective

Typical applications:

- General industrial heating

- Furnaces

- Kilns

- Heat treatment

Type K thermocouples are commonly supplied by Pyrosales in a wide variety of probe styles, sheath materials, and mounting configurations.

Type J Thermocouples.

Type J thermocouples use Iron and Constantan conductors.

Characteristics:

- Suitable for moderate temperature ranges

- Good sensitivity

- Limited oxidation resistance at high temperatures

Typical applications:

- Plastics processing

- Older industrial equipment

- Controlled atmospheres

These thermocouples use platinum-based alloys and are designed for very high temperature applications.

Characteristics:

- Exceptional stability at high temperatures

- High accuracy

- Significantly higher cost

Typical applications:

- Glass manufacturing

- Semiconductor processing

- Laboratory and calibration environments

Application-Driven Thermocouple Selection

Selecting the correct thermocouple is never just about temperature range. The application environment determines the most suitable combination of materials, construction, and configuration.

Process Environment

Consider whether the thermocouple will be exposed to:

- Oxidising or reducing atmospheres

- Corrosive gases or liquids

- High pressure

- Mechanical vibration

The answers directly influence sheath material selection and junction type.

Measurement Accuracy Requirements

While thermocouples are not as inherently accurate as RTDs, appropriate design, calibration, and signal conditioning can provide excellent performance for most industrial processes.

Pyrosales offers calibration and testing services to ensure thermocouples meet required tolerances.

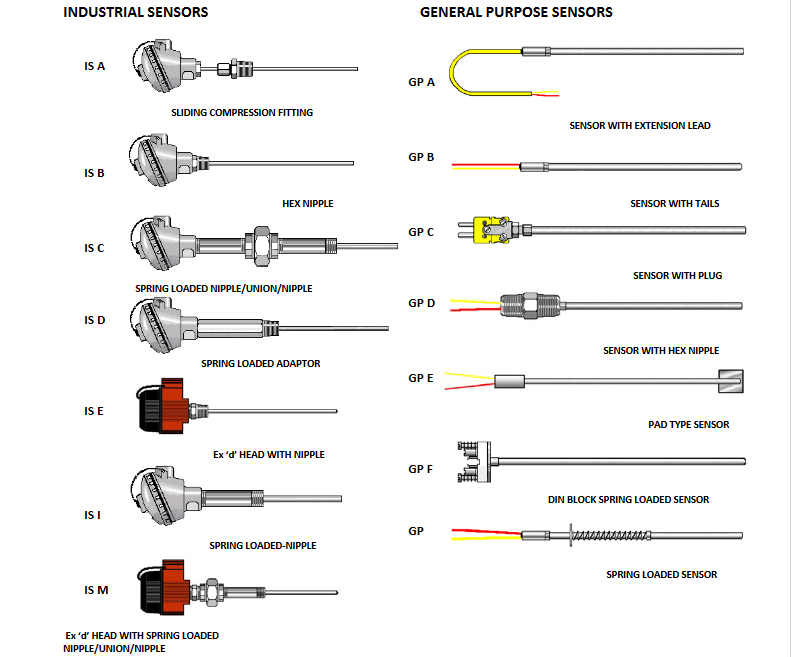

Installation Constraints

Physical constraints such as:

- Available insertion depth

- Space limitations

- Existing threaded or flanged connections

must be considered during sensor design.

Role of Pyrosales in Thermocouple Design and Supply

Capabilities include:

- Custom thermocouple fabrication

- Selection of sheath materials and junction types

- Integration with thermowells and process fittings

- Repair and refurbishment of existing sensors

- Technical consultation and application support

This expertise allows Pyrosales to support complex applications where standard catalogue sensors are inadequate.

Thermocouple Construction: Understanding the Anatomy of a Sensor

While thermocouples are often discussed in terms of “type” (K, J, R, etc.), the physical construction of the thermocouple is just as important as the alloy combination. Poor construction choices can lead to inaccurate readings, shortened sensor life, or outright failure in demanding environments.

A well-designed industrial thermocouple balances thermal performance, mechanical strength, chemical resistance, and installation practicality.

Core Components of an Industrial Thermocouple

A complete thermocouple assembly typically consists of:

- Thermocouple element (dissimilar metal pair)

- Measuring junction

- Electrical insulation

- Protective sheath

- Process connection or mounting hardware

- Extension wire or cable

- Connector or termination

Each component must be selected with the application in mind.

Thermocouple Probe Diameter and Length

Why Probe Diameter Matters

The probe diameter directly influences:

- Response time

- Mechanical strength

- Resistance to vibration

- Maximum operating temperature

Smaller diameter probes:

- Faster response times

- More sensitive to vibration and mechanical damage

- Shorter lifespan in abrasive environments

Larger diameter probes:

- Slower response

- Increased durability

- Better suited to harsh industrial conditions

In high-vibration environments such as furnaces, kilns, or rotating machinery, larger diameters are often preferred despite the slower thermal response.

Selecting Probe Length

Probe length affects both measurement accuracy and sensor survivability.

Key considerations include:

- Adequate immersion depth

- Avoidance of heat conduction errors

- Mechanical clearance and installation constraints

As a general guideline, the sensing junction should be immersed at least 10 times the probe diameter into the process medium to minimise stem conduction effects.

Pyrosales regularly assists customers in determining optimal probe lengths based on real-world process conditions.

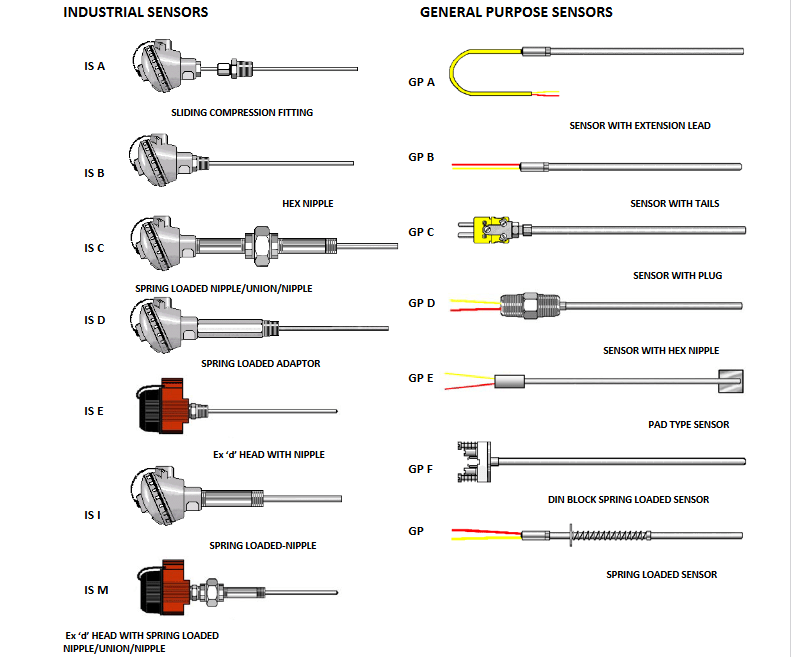

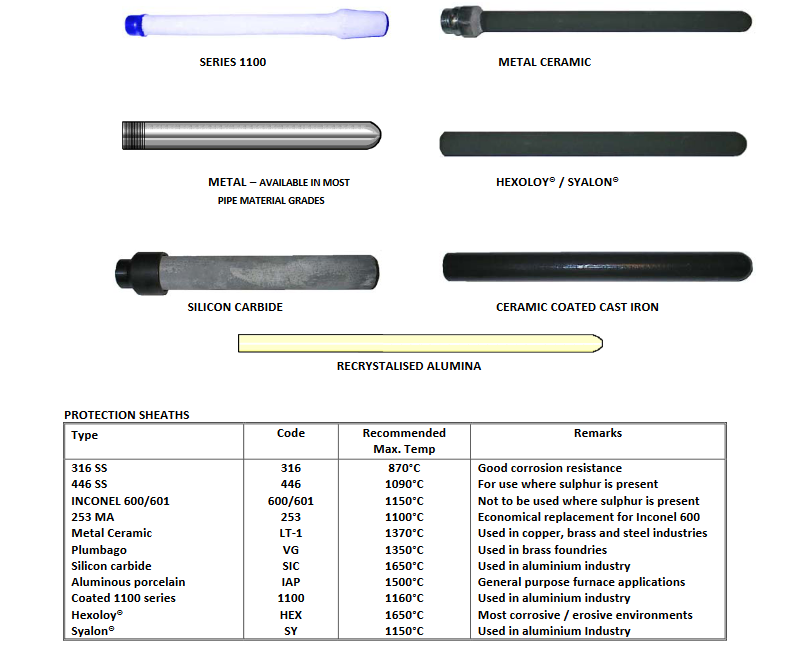

Sheath Materials: Protection Against Harsh Environments

The sheath material is one of the most critical design decisions when specifying a thermocouple. It provides mechanical protection while also acting as the interface between the sensing element and the process environment.

Common Sheath Materials

- Good general-purpose corrosion resistance

- Suitable for many industrial environments

- Moderate temperature capability

Inconel

- Excellent high-temperature strength

- Superior oxidation resistance

- Commonly used in furnaces and heat treatment applications

- Extremely high temperature capability

- Excellent chemical resistance

- Fragile compared to metal sheaths

Exotic Alloys

- Used for highly corrosive or specialised environments

- Typically selected for petrochemical or chemical processing

Matching Sheath Material to Application

Choosing the wrong sheath material can lead to:

- Premature sensor failure

- Contamination of the process

- Measurement drift due to corrosion or oxidation

Pyrosales leverages application-specific experience to recommend sheath materials that provide the best balance between durability and cost.

Insulation Materials and Their Role

Inside the sheath, thermocouple wires must be electrically insulated from each other and from the sheath.

Common Insulation Materials

- Magnesium Oxide (MgO)

- Ceramic fibre insulation

- Glass fibre insulation (lower temperature applications)

MgO is widely used in mineral-insulated thermocouples due to its:

- High dielectric strength

- Excellent thermal conductivity

- Stability at high temperatures

Proper insulation selection ensures signal integrity and long-term reliability.

Thermocouple Junction Types Explained in Detail

The junction type plays a major role in thermocouple performance, response time, and resistance to electrical noise.

Grounded Junction Thermocouples

In grounded junction designs, the thermocouple junction is welded directly to the inside of the sheath.

Advantages:

- Fast response time

- Good heat transfer

- Suitable for high-pressure environments

Disadvantages:

- Susceptible to electrical noise

- Potential ground loop issues

Grounded junction thermocouples are commonly used in industrial processes where rapid temperature changes must be detected.

Ungrounded Junction Thermocouples

In ungrounded designs, the junction is electrically isolated from the sheath.

Advantages:

- Reduced electrical interference

- Improved signal stability

- Suitable for sensitive measurement systems

Disadvantages:

- Slightly slower response than grounded designs

Ungrounded junctions are often preferred in electrically noisy environments or when connected to sensitive control systems.

Exposed Junction Thermocouples

Exposed junction thermocouples have no protective sheath at the sensing point.

Advantages:

- Fastest response time

- Direct exposure to process medium

Disadvantages:

- Limited mechanical protection

- Not suitable for corrosive or high-pressure environments

These are typically used in gas measurement or laboratory environments.

Thermowells and Mechanical Protection

Purpose of Thermowells

Thermowells:

- Protect sensors from mechanical damage

- Allow sensor replacement without process shutdown

- Isolate the sensor from corrosive or high-pressure media

Thermowell Design Considerations

Key design factors include:

- Material selection

- Insertion length

- Bore diameter

- Flow-induced vibration resistance

Incorrect thermowell design can result in resonance and fatigue failure. Pyrosales provides guidance to ensure thermowell designs meet industry standards and application requirements.

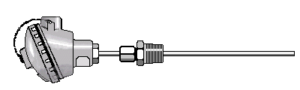

Process Connections and Mounting Options

Thermocouples must be securely mounted to ensure accurate measurement and safe operation.

Common Mounting Methods

- Threaded fittings

- Flanged connections

- Compression fittings

- Bayonet fittings

Each method has advantages depending on accessibility, pressure, and installation constraints.

Sealing and Leak Prevention

Proper sealing is essential in pressurised or hazardous environments. Selecting appropriate fittings and gaskets helps prevent leaks and ensures compliance with safety regulations.

Extension Wires, Cables, and Connectors

Extension wire must be made from compatible alloys to avoid introducing measurement errors.

Cable Insulation

Cable insulation should be chosen based on:

- Ambient temperature

- Chemical exposure

- Mechanical stress

Connectors

Correct connectors ensure reliable signal transmission and ease of maintenance.

Installation Best Practices

Immersion Depth

Insufficient immersion depth can cause heat conduction errors.

Avoiding Electrical Interference

- Use proper grounding

- Separate thermocouple wiring from power cables

- Select appropriate junction type

Mechanical Support

Provide adequate strain relief and support to prevent vibration-induced damage.

Maintenance and Sensor Life Expectancy

Thermocouple lifespan depends on:

- Operating temperature

- Thermal cycling frequency

- Chemical exposure

- Mechanical stress

Routine inspection and preventative maintenance can extend sensor life and reduce unplanned downtime.

Pyrosales offers repair and refurbishment services to help extend the life of existing sensors.

Understanding Thermocouple Alloys and Performance Characteristics

At the core of every thermocouple is a pair of dissimilar metal alloys. The specific alloy combination determines the thermocouple’s temperature range, sensitivity, stability, and resistance to environmental influences such as oxidation or corrosion.

While thermocouple “types” are often treated as interchangeable, in reality each alloy behaves differently under thermal and chemical stress. Selecting the wrong type can lead to drift, premature failure, or misleading readings.

Key Performance Factors of Thermocouple Alloys

When evaluating thermocouple alloys, engineers must consider:

- Maximum continuous operating temperature

- Sensitivity (microvolts per degree)

- Resistance to oxidation or contamination

- Stability under thermal cycling

- Cost and availability

These factors vary significantly between base-metal and noble-metal thermocouples.

Base-Metal Thermocouples

Base-metal thermocouples are the most widely used in industrial environments due to their cost-effectiveness, durability, and broad operating ranges.

Type K Thermocouples (Nickel-Chromium / Nickel-Aluminium)

Key characteristics:

- Wide operating range (approximately −200 °C to 1,250 °C)

- Good resistance to oxidation

- Suitable for both oxidising and inert atmospheres

- Relatively high sensitivity

Typical applications:

- Industrial furnaces

- Kilns

- Heat treatment

- Plastics and rubber processing

- General manufacturing

Type K thermocouples are widely supported by control systems and instrumentation, making them easy to integrate into existing processes. Pyrosales commonly supplies Type K thermocouples in mineral-insulated and heavy-duty industrial formats.

Type J Thermocouples (Iron / Constantan)

Type J thermocouples are commonly used in moderate temperature applications.

Key characteristics:

- Operating range up to approximately 750 °C

- High output signal

- Limited oxidation resistance at elevated temperatures

Typical applications:

- Plastics processing

- Legacy industrial equipment

- Vacuum or controlled atmospheres

Type T Thermocouples (Copper / Constantan)

Type T thermocouples are particularly well suited to low-temperature and cryogenic applications.

Key characteristics:

- Excellent accuracy at low temperatures

- Stable and repeatable

- Narrower temperature range

Typical applications:

- Refrigeration systems

- Food processing

- Laboratory environments

Type E Thermocouples (Nickel-Chromium / Constantan)

Type E thermocouples provide one of the highest sensitivities among base-metal thermocouples.

Key characteristics:

- High output voltage

- Suitable for low-temperature measurement

- Limited high-temperature capability

Typical applications:

- Cryogenic measurement

- Precision low-temperature applications

Type N Thermocouples (Nicrosil / Nisil)

Type N thermocouples were developed to address some of the limitations of Type K thermocouples, particularly long-term drift at high temperatures.

Key characteristics:

- Improved stability at high temperatures

- Better resistance to oxidation

- Reduced drift compared to Type K

Typical applications:

- High-temperature furnaces

- Long-term continuous processes

- Aerospace and power generation

Noble-Metal Thermocouples

Noble-metal thermocouples use platinum-based alloys and are designed for very high-temperature and high-accuracy applications.

Type R Thermocouples (Platinum / Platinum-Rhodium)

Key characteristics:

- Operating range up to approximately 1,600 °C

- Excellent stability and accuracy

- High cost

Typical applications:

- Glass manufacturing

- Semiconductor processing

- Calibration laboratories

Type S Thermocouples (Platinum / Platinum-Rhodium)

Type S thermocouples are similar to Type R but offer slightly different performance characteristics.

Typical applications:

- High-temperature industrial processes

- Reference temperature measurement

- Calibration standards

Type B Thermocouples (Platinum-Rhodium / Platinum-Rhodium)

Type B thermocouples are designed for extreme temperatures.

Key characteristics:

- Operating range up to approximately 1,700 °C

- Stable at very high temperatures

- Lower sensitivity at lower temperatures

Typical applications:

- Glass furnaces

- High-temperature metallurgy

- Advanced ceramics

Environmental Influences on Thermocouple Performance

Even the correct thermocouple type can perform poorly if environmental influences are not considered.

Oxidising and Reducing Atmospheres

Certain alloys degrade rapidly in reducing or sulphurous atmospheres. Selecting appropriate sheath materials and thermocouple types is critical.

Chemical Contamination

Exposure to chemicals such as sulphur, halogens, or molten metals can contaminate thermocouple alloys, leading to drift or failure.

Thermal Cycling

Repeated heating and cooling can cause mechanical stress, particularly at the junction. Proper design helps mitigate fatigue.

Industry-Specific Thermocouple Applications

Furnaces and Kilns

Furnaces and kilns represent some of the most demanding thermocouple applications.

Key requirements:

- High temperature capability

- Resistance to oxidation and scale formation

- Mechanical robustness

Common solutions include Type K, Type N, and noble-metal thermocouples with Inconel or ceramic sheaths.

Heat Treatment and Metallurgy

Heat treatment processes require precise temperature control to ensure material properties.

Typical challenges:

- Long dwell times at high temperatures

- Thermal cycling

- Exposure to protective atmospheres

Glass Manufacturing

Glass production involves extremely high temperatures and chemically aggressive environments.

Key considerations:

- Noble-metal thermocouples

- Ceramic protection tubes

- Long-term stability

Petrochemical and Chemical Processing

Chemical processing environments may expose sensors to corrosive substances, high pressures, and hazardous conditions.

Typical solutions:

- Robust metal sheaths

- Thermowells

- Ungrounded junctions to reduce electrical interference

Food and Beverage Processing

Key considerations:

- Lower temperature ranges

- Cleanability

- Compliance with industry standards

Type T and Type K thermocouples are commonly used, often in hygienic probe designs.

Power Generation

Power plants rely on temperature measurement for efficiency and safety.

Applications include:

- Boilers

- Turbines

- Exhaust systems

Thermocouples must withstand high temperatures, vibration, and long operating cycles.

Accuracy, Drift, and Calibration Considerations

Understanding Thermocouple Accuracy

- Alloy tolerances

- Junction construction

- Installation quality

- Signal conditioning

Long-Term Drift

Drift occurs due to:

- Alloy contamination

- Oxidation

- Grain growth at high temperatures

Type N and noble-metal thermocouples offer improved stability for long-term use.

Calibration and Verification

Regular calibration ensures measurement accuracy and compliance with quality standards.

Pyrosales provides calibration support to verify sensor performance and identify drift before it affects process outcomes.

Selecting the Right Thermocouple: A Decision Framework

When selecting a thermocouple, engineers should evaluate:

- Maximum and minimum operating temperature

- Process atmosphere

- Mechanical stress and vibration

- Required response time

- Accuracy and stability requirements

- Installation and maintenance constraints

- Budget and lifecycle cost

This structured approach helps avoid common selection errors.

Advanced Thermocouple Installation Practices

Even the most carefully selected thermocouple can produce inaccurate or unreliable readings if it is poorly installed. Installation directly affects measurement accuracy, response time, sensor lifespan, and safety.

Correct Sensor Placement

Key placement principles include:

- Positioning the junction in the centre of the process medium

- Avoiding contact with vessel walls unless surface measurement is intended

- Minimising exposure to radiant heat sources unless specifically required

Incorrect placement is one of the most common causes of temperature measurement error.

Immersion Depth and Thermal Conduction Errors

If a thermocouple is not immersed sufficiently, heat can conduct away from the sensing junction along the probe stem, resulting in lower-than-actual readings.

General guidelines include:

- Minimum immersion depth of 10–15 times the probe diameter

- Greater immersion for low-conductivity fluids

- Consideration of thermowell bore clearance

Orientation and Flow Considerations

In flowing media, thermocouples should ideally be oriented:

- Perpendicular to flow for best heat transfer

- Avoiding wake zones behind obstructions

- Away from areas of turbulence that may cause vibration

Correct orientation improves response time and reduces mechanical stress.

Electrical Installation and Noise Reduction

Thermocouples generate small voltage signals, typically in the microvolt range. As a result, they are particularly susceptible to electrical noise and interference.

Common Sources of Electrical Interference

- Variable speed drives (VSDs)

- High-current power cables

- Electric heaters

- Ground loops

Electrical interference can manifest as unstable or erratic temperature readings.

Grounding Best Practices

Grounding strategy depends on the junction type:

- Grounded junctions require careful grounding to avoid loops

- Ungrounded junctions provide inherent electrical isolation

Best practices include:

- Single-point grounding

- Avoiding multiple earth paths

- Using shielded cables where appropriate

Cable Routing and Separation

Thermocouple wiring should be routed separately from power cables to minimise electromagnetic interference.

Recommended practices:

- Maintain physical separation

- Cross power cables at right angles if unavoidable

- Use cable trays or conduits designed for instrumentation wiring

Thermocouple Signal Conditioning

Because thermocouple output is non-linear and reference-junction dependent, proper signal conditioning is essential.

Cold Junction Compensation (CJC)

Thermocouples measure temperature difference, not absolute temperature. Cold junction compensation accounts for the reference junction temperature to provide accurate readings.

CJC can be implemented via:

- Internal compensation in instruments

- External temperature sensors

- Dedicated compensation modules

Linearisation

Thermocouple voltage-temperature relationships are non-linear. Modern instrumentation uses digital linearisation algorithms to convert voltage into accurate temperature readings.

Signal Amplification

In long cable runs or noisy environments, amplification may be required to improve signal integrity.

Thermocouple Instrumentation and Integration

Thermocouples are only as effective as the instrumentation interpreting their signals.

Temperature Controllers

Key controller features include:

- Input type compatibility

- Control accuracy

- PID tuning capabilities

- Communication interfaces

Transmitters

Transmitters convert thermocouple signals into standardised outputs such as 4–20 mA or digital protocols.

Benefits include:

- Improved noise immunity

- Long-distance signal transmission

- Integration with PLC and DCS systems

PLC and SCADA Integration

Thermocouples are commonly connected to PLC input modules for process control and monitoring.

Considerations include:

- Input resolution

- Sampling rate

- Built-in cold junction compensation

Controllers, Indicators, and Displays

I

Panel-Mounted Indicators

These provide real-time temperature display for operators.

Handheld Thermocouple Meters

Used for diagnostics, commissioning, and maintenance activities.

Redundancy and Safety Monitoring

Critical processes may use redundant thermocouples to improve safety and reliability.

Common Thermocouple Installation Errors

Understanding common errors helps prevent costly troubleshooting later.

Incorrect Thermocouple Type Selection

Using the wrong thermocouple type or extension wire can introduce significant errors.

Poor Junction Contact

Loose or improperly formed junctions reduce response time and accuracy.

Inadequate Mechanical Support

Vibration can cause conductor fatigue and intermittent failures.

Environmental Damage

Exposure to moisture, chemicals, or excessive heat can degrade insulation and wiring.

Troubleshooting Thermocouple Problems

When a thermocouple system produces unexpected results, systematic troubleshooting is required.

Erratic Readings

Possible causes:

- Electrical interference

- Loose connections

- Ground loops

Slow Response Time

- Excessive probe diameter

- Poor immersion

Drift Over Time

Possible causes:

- Alloy contamination

- Oxidation

- Prolonged exposure to high temperatures

Complete Signal Loss

Possible causes:

- Broken conductors

- Connector failure

- Instrument input faults

Preventative Maintenance Strategies

Regular maintenance helps ensure consistent performance and avoids unplanned downtime.

Inspection Intervals

Inspection frequency depends on:

- Operating temperature

- Environmental severity

- Process criticality

Replacement Planning

High-temperature thermocouples may be considered consumable items in some processes.

Documentation and Traceability

Maintaining records of installation dates, calibration results, and replacements helps identify trends and optimise maintenance schedules.

Safety Considerations in Thermocouple Applications

High-Temperature Hazards

Thermocouples in furnaces and boilers must be designed to withstand extreme conditions without failing catastrophically.

Hazardous Areas

In explosive or hazardous environments, thermocouples must comply with relevant standards and installation practices.

Fail-Safe Design

Fail-safe instrumentation ensures that loss of signal triggers protective actions rather than unsafe operation.

Why Standard Thermocouples Are Not Always Enough

While many industrial applications can be served by standard, catalogue thermocouples, a significant number of processes operate outside “ideal” conditions. High temperatures, aggressive atmospheres, unusual mechanical constraints, or regulatory requirements often demand custom-engineered solutions.

Standard thermocouples may fall short due to:

- Insufficient sheath materials

- Inadequate probe geometry

- Limited mounting options

- Short service life

- Poor compatibility with existing systems

Custom thermocouples address these limitations by tailoring each element of the sensor to the application.

Custom Thermocouple Design Considerations

Custom thermocouple design involves optimising every component of the sensor assembly.

Defining the Process Requirements

The first step in custom design is understanding the process in detail:

- Operating temperature range (continuous and peak)

- Atmosphere (oxidising, reducing, inert, corrosive)

- Mechanical stresses (vibration, shock, abrasion)

- Pressure and flow conditions

- Installation constraints and accessibility

This information guides material selection and mechanical design.

Selecting the Optimal Thermocouple Type

While Type K remains a common default, custom designs may benefit from:

- Type N for improved stability at high temperatures

- Noble-metal thermocouples for extreme heat

- Special alloy combinations for niche environments

The choice is driven by performance and longevity, not just upfront cost.

Advanced Materials and Protective Strategies

Multi-Layer Sheath Designs

In aggressive environments, a single sheath material may not provide sufficient protection. Multi-layer designs combine materials to improve resistance to:

- Chemical attack

- Thermal shock

- Mechanical wear

Ceramic and Refractory Protection

Ceramic protection tubes are often used in glass and high-temperature furnace applications. While fragile, they offer excellent resistance to extreme heat and chemical exposure.

Thermowells for Sensor Longevity

Thermowells act as sacrificial components that protect the thermocouple from process conditions while allowing replacement without shutdown.

Proper thermowell design is essential to prevent vibration-induced fatigue.

Integration with Existing Plant Infrastructure

Mechanical Compatibility

Custom fittings ensure compatibility with:

- Existing threaded ports

- Flanges

- Compression fittings

This reduces installation time and avoids costly modifications.

Electrical Compatibility

Signal compatibility with existing controllers, PLCs, and transmitters is critical.

Custom designs may include:

- Specific connector types

- Pre-terminated cables

- Shielded wiring

Lifecycle Cost vs. Purchase Price

One of the most common mistakes in thermocouple selection is focusing solely on initial purchase price.

Understanding Total Cost of Ownership (TCO)

Total cost of ownership includes:

- Initial purchase cost

- Installation labour

- Downtime during replacement

- Calibration and maintenance

- Premature failure and rework

A more expensive thermocouple with longer life and improved reliability often results in lower overall cost.

Consumable vs. Long-Life Sensors

In some processes, thermocouples are treated as consumables. In others, long-life designs justify higher upfront investment.

Understanding this distinction helps optimise cost and performance.

Calibration, Traceability, and Quality Assurance

Importance of Calibration

Calibration verifies that thermocouples are operating within specified tolerances.

Regular calibration:

- Maintains process accuracy

- Supports quality systems (ISO, HACCP, etc.)

- Identifies drift before it impacts production

Traceability Requirements

Proper documentation ensures compliance and audit readiness.

Repair, Refurbishment, and Sensor Reuse

Replacing a thermocouple is not always the most cost-effective solution.

When Repair Is Viable

Repair may be possible when:

- The sensing element remains intact

- Damage is limited to leads or connectors

- Sheath integrity is maintained

Benefits of Refurbishment

Refurbishment reduces:

- Waste

- Lead time

- Cost

Pyrosales supports repair and refurbishment services to extend sensor life where feasible.

Common Selection Mistakes and How to Avoid Them

Over-Specifying Accuracy

In many industrial processes, extreme accuracy is unnecessary. Over-specification increases cost without improving outcomes.

Underestimating Environmental Severity

Failing to account for corrosion, vibration, or thermal cycling leads to premature failure.

Ignoring Installation Constraints

Even the best sensor will fail if it cannot be installed correctly.

Thermocouple Selection Checklist

Before finalising a thermocouple specification, confirm the following:

- ✔ Operating temperature range

- ✔ Process atmosphere

- ✔ Required response time

- ✔ Mechanical stresses

- ✔ Installation method

- ✔ Electrical compatibility

- ✔ Calibration requirements

- ✔ Maintenance strategy

Using this checklist reduces selection errors and improves long-term performance.

Summary: Choosing the Right Thermocouple with Confidence

Choosing the right thermocouple requires balancing technical requirements, environmental conditions, installation constraints, and lifecycle costs.

Key takeaways include:

- Thermocouples remain the most versatile solution for industrial temperature measurement

- Proper selection goes beyond thermocouple type

- Construction, materials, and installation are equally important

- Custom solutions often provide superior performance and lower lifecycle cost

- Expert support reduces risk and improves reliability

Why Work with Pyrosales

- Industrial thermocouples

- RTDs and temperature probes

- Custom-engineered solutions

- Calibration and testing

- Repair and refurbishment

By working with Pyrosales, customers gain access to practical engineering knowledge, not just products.

Final Thoughts

Accurate temperature measurement is fundamental to safe, efficient, and profitable industrial operations. Thermocouples, when correctly selected and installed, provide reliable performance across a wide range of applications.

Whether you require a standard sensor or a custom-engineered solution, taking a systematic, informed approach ensures the best possible outcome.