What is a Thermometer?

What are the Origins of the Thermometer?

Santorii is regarded as the inventor of the thermometer, for he published the earliest account of a thermometer in 1612.

How does a Thermometer work?

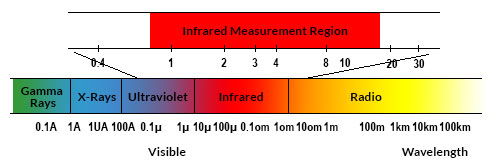

Infrared thermometers measure temperature from a distance.

Who uses Thermometers?

The applications of use for infrared thermometer is quite extensive. They are frequently used in industrial processes, the professional sector and in particular to monitor mains supply units or to measure the temperature of components in motors or machines. The Glass industries, Electrical industries use many forms of the thermometers. The Medical sector also uses many forms in hospitals to in peoples own homes.

Thermometer that Pyrosales is offering.

Pyrosales is a distributor of TESTO products which include a wide range of thermometers.

The two latest thermometer for industrial usage are the Testo 835-T1 and 835-T2.

Checking the function of underfloor heating

Temperature measurement of underfloor heating when it is installed or when maintenance or servicing is being carried out. Ensuring the underfloor heating is functioning properly by measuring the temperature at various points on it.

Advantages of the testo 835-T1:

- Fast, easy (non-contact) checking of underfloor heating

- Fast saving and documentation of data for later report writing

- Clear marking of the measuring range by 4-point laser

Checking switch cabinets, fuses and fitted cables

Temperature measurement of electrical installations when they are installed or when maintenance or servicing is being carried out. Ensuring the electrical components are functioning properly by measuring the temperature at various points on them.

Advantages of the testo 835-T1:

- Fast, easy, non-contact checking of electrical components

- Fast saving and documentation of data for later report writing

- Clear marking of the measuring range by 4-point laser

Checking ventilation components

The testo 835-T1 is ideally suited for measuring the temperature of ventilation components, for instance at duct outlets and on ventilation ducts. Assessing the ventilation duct’s insulation and ensuring the ventilation system is functioning properly by temperature measurement.

Advantages of the testo 835-T1:

Measuring of ducts and outlets at a great distance

- Easy scanning of ducts

- Fast saving of measuring values in the instrument

- Comparison with previous measuring values to identify any changes

Surface temperature measurement on bearings and gear mechanisms

Non-contact surface temperature measurement on industrial production machines for preventive maintenance. Especially measurement of bearings and gear mechanisms to prevent superheating. Preventing production downtime due to machines failing as a result of superheating.

Advantages of the testo 835-T1:

- Fast and precise measurement from a safe and long distance

- Clear marking of the measuring range by 4-point laser

- Possibility of monitoring and logging the temperature profile by long-term measurement (only in combination with EasyClimate PC software, a free download via testo.de)

Surface temperature measurement for quality control

Product quality assurance for various industrially manufactured products: e.g. in the production process to determine whether the required temperature has been reached for further processing of the product, or when cooling products.

Advantages of the testo 835-T1: Fast and precise measurement from a safe and long distance

- Integrated emission level table and automatic determination of the emission level enable a rapid selection of the right emission level for various surfaces

- Clear marking of the measuring range by 4-point laser

- Possibility of monitoring and logging the temperature profile by long-term measurement (only in combination with Easy Climate PC software, a free download via testo.de)

Measurement of heat distribution in radiators

The testo 835-T1 is ideally suited for measuring the temperature of radiators when they are installed or when maintenance or servicing is being carried out. Ensuring the radiator is functioning properly by measuring the temperature at various points on it.

Advantages of the testo 835-T1:

- Fast, easy, non-contact checking of radiators

- Fast saving and documentation of data for later report writing

- Clear marking of the measuring range by 4-point laser

Testo 835-T2: Measure precise temperatures of up to 1500 °C from a safe distance thanks to its extended temperature measuring range, testo 835T2 can be used virtually all sectors of trade and industry: e.g. monitoring wall temperature and, inspecting air conditioning and ventilation systems, the maintenance of industrial systems or the quality control of industrially manufactured products.

Product temperature monitoring for quality control in glass, ceramics and metal industries up to 1,500°C

The testo 835-T2 is ideally suited for product quality assurance for various industrially manufactured products: e.g. in the production process to determine whether the required temperature has been reached for further processing of the product, or when cooling products.

Advantages of the testo 835-T2:Fast and precise measurement from a safe and long distance

- Integrated emission level table and automatic determination of the emission level enable a rapid selection of the right emission level for various surfaces

- Clear marking of the measuring range by 4-point laser

- Possibility of monitoring and logging the temperature profile by long-term measurement (only in combination with Easy Climate PC software, a free download via testo.de)