What is a Thermocouple and what are the Types of Thermocouples?

What is a Thermocouple?

The two wires forming the thermocouple are welded together at one end to create a junction—the location where the temperature is measured. When this junction experiences a temperature change, an electromotive force (EMF) is generated due to the Seebeck Effect. This small voltage can then be interpreted using calibration tables or electronic systems to determine the temperature.

The Seebeck Effect and Thermoelectric Properties

A common misconception is that the EMF is generated solely at the tip or junction of the thermocouple. However, the EMF is distributed throughout the lengths of both legs of the thermocouple. The total EMF produced is the difference between the EMFs in the two legs, which depends on the Seebeck coefficient of the materials used. The Seebeck Effect, discovered by Thomas Seebeck in 1821, describes the phenomenon where a temperature difference between two dissimilar conductors or semiconductors creates a voltage difference.

The Seebeck coefficient, a measure of how electrons interact with the metal lattice and grain structure, is highly sensitive to changes in the metal’s physical and chemical properties. Factors such as contamination, oxidation, mechanical strain, or heat treatment can alter the Seebeck coefficient, leading to variations in the thermocouple’s output. As thermocouples are often subjected to non-uniform temperature fields during usage, these changes can create a thermoelectric “signature,” affecting their accuracy.

One critical consideration is the immersion depth of the thermocouple. For instance, reducing the immersion depth of a nickel-based thermocouple can cause significant output changes, potentially leading to errors as large as 15°C. To maintain accuracy, thermocouples should be installed in a fixed position and used under consistent conditions.

Types of Thermocouples

Thermocouples come in a variety of types, each tailored for specific applications, temperature ranges, and environmental conditions. The most common types include:

Base Metal Thermocouples

1. Type K (Chromel-Alumel):

• Temperature Range: -200°C to +1,260°C

• Applications: Industrial processes, HVAC systems, furnaces, engines, and exhaust monitoring.

• Features: Durable, versatile, and performs well in oxidizing environments.

2. Type J (Iron-Constantan):

• Temperature Range: -40°C to +750°C

• Applications: Legacy industrial systems and moderate-range temperature monitoring.

• Features: Cost-effective but prone to rust in moist conditions.

3. Type T (Copper-Constantan):

• Temperature Range: -200°C to +350°C

• Applications: Cryogenics, food processing, and refrigeration.

• Features: High accuracy, excellent for sub-zero temperatures.

4. Type E (Chromel-Constantan):

• Temperature Range: -200°C to +900°C

• Applications: Scientific instrumentation and calibration systems.

• Features: High sensitivity and accuracy.

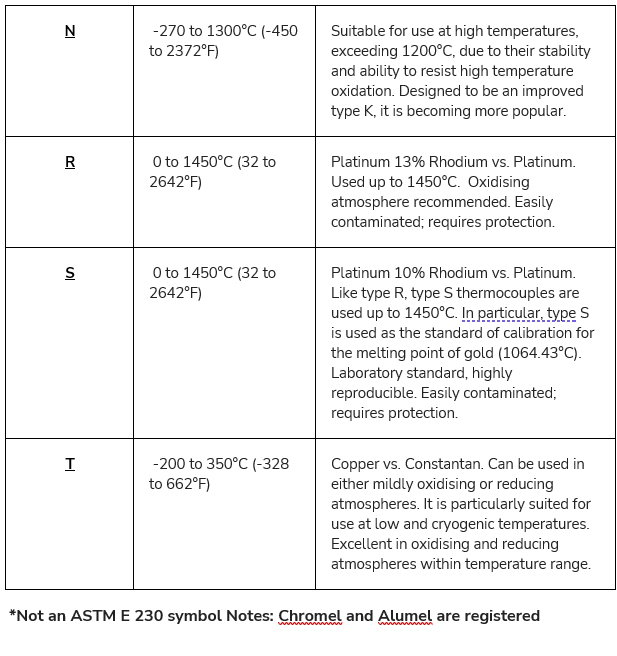

5. Type N (Nicrosil-Nisil):

• Temperature Range: -200°C to +1,260°C

• Applications: High-temperature industrial processes, petrochemical, and aerospace applications.

• Features: Stable and resistant to oxidation.

1. Type S (Platinum-Rhodium 10%):

• Temperature Range: 0°C to +1,450°C

• Applications: Pharmaceutical, high-temperature furnaces, and kilns.

• Features: Highly stable and accurate, suitable for extreme conditions.

2. Type R (Platinum-Rhodium 13%):

• Temperature Range: 0°C to +1,450°C

• Applications: Precision laboratories and glass manufacturing.

• Features: Similar to Type S with slightly enhanced performance.

3. Type B (Platinum-Rhodium 30%):

• Temperature Range: +100°C to +1,800°C

• Applications: Steel and ceramic industries, aerospace, and extreme high-temperature environments.

• Features: Exceptional stability at elevated temperatures.

Applications of Thermocouples

Thermocouples are integral to many industries and applications due to their versatility, durability, and ability to measure a wide range of temperatures. Common usage includes:

• Industrial Applications: Power generation, mining, oil and gas, cement, paper, and glass manufacturing.

• Scientific Research: Laboratories and calibration systems.

• Everyday Appliances: Stoves, furnaces, kilns, and ovens.

• Specialized Applications: Cryogenics, high-temperature furnaces, and aerospace systems.

Advantages of Thermocouples

Thermocouples are widely chosen for their:

• Wide Temperature Ranges: Suitable for both cryogenic and extremely high-temperature applications.

• Durability: Resistant to harsh environments.

• Cost-Effectiveness: Affordable compared to other temperature sensors.

• Fast Response Time: Rapid measurement of temperature changes.

Limitations of Thermocouples

Despite their advantages, thermocouples have certain limitations:

• Accuracy: Calibration is often required for high-precision applications.

• Drift Over Time: Prolonged exposure to extreme conditions can degrade performance.

• Non-Linearity: Voltage-to-temperature conversion requires compensation for accurate readings.

• Lifespan: Base-metal thermocouples degrade faster in corrosive or high-temperature environments.

History of Thermocouples

The origin of the thermocouple dates back to 1821 when Thomas Johann Seebeck discovered the Seebeck Effect. Over time, scientists such as Michael Faraday and Georg Ohm expanded on this discovery, paving the way for the development of practical thermocouples. By the early 1900s, thermocouples were being manufactured and have since evolved into essential tools for temperature measurement across industries.

Manufacturing of Thermocouples

Thermocouples are constructed by joining two metal alloys to form a junction. This junction, protected by insulated tubing, is placed in the environment where temperature measurement is needed. The choice of metal alloys determines the thermocouple’s temperature range and sensitivity. Manufacturers tailor thermocouples based on factors such as environment, required accuracy, and compatibility with existing systems.

Thermocouples are indispensable tools for temperature measurement, offering a wide range of applications and benefits. Selecting the appropriate thermocouple type requires careful consideration of the specific requirements, environmental conditions, and desired accuracy. Manufacturers like Pyrosales provide expert guidance to ensure the correct thermocouple is chosen for each application, ensuring reliable and efficient temperature management in various industries.