How Thermal Imaging Works and InfiRay Thermal Imaging Cameras?

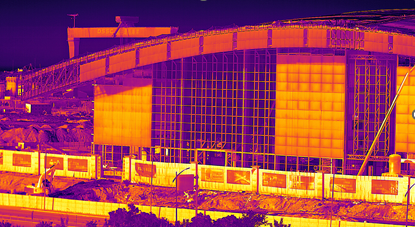

In the realm of modern technology, few innovations have proven as transformative and versatile as thermal imaging. The ability to visualise and interpret the invisible heat signatures emitted and objects has revolutionised industries ranging from manufacturing to fire fighting.

What where the early days of Infrared Radiation and Thermal Imaging Cameras?

Herschel’s experiment led to the discovery of infrared radiation, while studying the temperature difference across the visible spectrum, the experiment showed a warmer temperature beyond the red end hence the birth of understanding IR radiation.

Infrared extends our vision beyond visible light, allowing us to explore the heat energy emitted by objects. Technology advancements in infrared CCD imaging systems (A charge-coupled device

The thermal imaging concept emerged in the early 20th century, in 1929 Hugarian physicist Kálmán Tihanyi invented the world’s first infrared-sensitive (night vision) electronic television camera for anti-aircraft defence in Britian.

The Evolution of Thermal Imaging Cameras.

As technology advanced so did the thermal imaging cameras, each advancement offered something new to the generations of thermal imaging cameras. Improvements in sensitivity, resolution, efficiency, and applications.

The fundamental distinction between uncooled and cooled infrared camera cores lies in their cooling mechanisms. Cooled camera cores employ advanced cooling techniques, often involving cryogenic cooling, to reduce the temperature of the sensor. This cooling significantly enhances the sensitivity of the camera by reducing the thermal noise generated by the sensor itself. On the other hand, uncooled camera cores operate at ambient temperatures, relying on the sensor design and electronics to compensate for the thermal noise.

The cooling mechanism directly affects the sensitivity of the infrared camera core. Cooled camera cores, due to their reduced sensor temperature, exhibit higher sensitivity. This heightened sensitivity allows them to detect even the slightest temperature differences in the observed scene. This is especially crucial in applications where identifying subtle thermal variations is essential, such as in manufacturing industries, military reconnaissance, scientific research, and certain industrial processes. Uncooled camera cores, although less sensitive than their cooled counterparts, still offer respectable performance in various applications.

The cooling mechanisms in cooled camera cores contribute to their larger size and heavier weight compared to uncooled cores. The presence of cryogenic cooling systems and additional

The choice between uncooled and cooled infrared camera cores depends on the specific application requirements. Cooled camera cores find their niche in high-end applications where sensitivity and precision are crucial. These applications include long-range surveillance, scientific research, thermal imaging in extreme conditions, and military targeting systems. The enhanced sensitivity of cooled cores makes them well-suited for detecting hidden objects, monitoring wildlife, and conducting detailed thermal inspections.

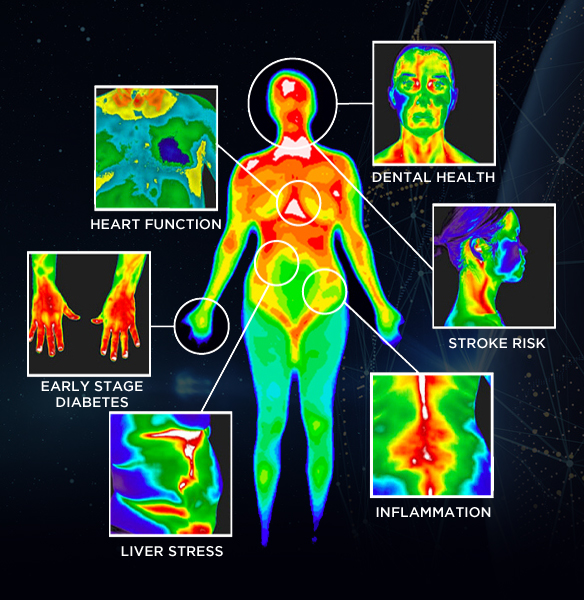

On the other hand, uncooled infrared camera cores are versatile and find use in a wide range of applications. They are commonly employed in commercial security systems, building inspections, firefighting, automotive night vision, and medical diagnostics. Uncooled cores are particularly valuable in applications that demand cost-effectiveness and portability without compromising on performance.

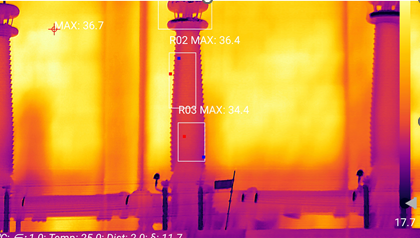

What are the vital Specifications of a thermal Imaging Camera?

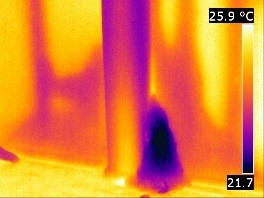

Pixel pitch refers to the distance between individual pixels on the thermal sensor. Smaller pixel pitch means higher pixel density, resulting in more detailed thermal images. Each pixel captures temperature information, and a smaller pixel pitch allows for better spatial resolution and accuracy. Pixel pitch directly affects the camera’s spatial resolution. With a smaller pixel pitch, the camera can detect smaller temperature variations and present a more detailed image. A thermal imaging camera with a smaller pixel pitch provides enhanced image clarity, making it ideal for applications requiring precise temperature measurement and identification of fine details.

Resolution is a crucial specification that determines the total number of pixels in the thermal image. Higher resolution means more pixels, resulting in sharper and more defined thermal images. Thermal imaging cameras come with varying resolution options, such as low, medium, and high. High-resolution cameras are suitable for applications that demand superior image quality and detailed analysis.

FOV (Field of View) is the area that the thermal imaging camera can capture in a single frame. A wider FOV covers a larger area, while a narrower FOV focuses on a smaller target region. They offer various FOV options, including wide-angle, narrow, and zoom. Each FOV type caters to different applications, such as surveillance, inspections, and research.

Where do we use thermal imaging?

Science and research are undoubtedly sectors that draw significant benefits from using thermal imagers, for accurate and precise visualisations of heat patterns such as dark side of the moon.

Money saving is something you wouldn’t necessarily expect from a thermal imaging device, but when you think about everything it can do, it makes sense. After the upfront cost of purchasing the device, they can undoubtedly save your business or home thousands of dollars or more in potential maintenance and repair costs that might incur if faults, leaks, or weaknesses were not identified earlier.

However, it’s important to recognise that while thermal imaging has all these applications, it’s often best to use additional instruments or tools when appropriate to confirm what you’re seeing. Additionally, it’s worth noting that thermal imaging cameras are unable to see through walls and objects, but rather, they only pick up what’s reflected off them.

Choosing and purchasing a high-quality thermal imaging Camera

Here at Pyrosales we are proud to offer a wide range of Thermal imaging Cameras suitable for all kinds of applications, whether they be professional or hobbyist. Our suite of top-range thermal imagers is made by InfiRay, a globally active, high-tech company with an expertise in innovative measurement solutions that are guaranteed to meet your needs.

Thermal imaging is an impressive and compact method of identifying, measuring and visualising heat patterns, particularly in environments where there’s a lack of visible light. Armed with an effective and high-quality thermal imaging camera, there are a broad range of applications available, from industrial to health to research and science and so much more.