Vinyl record manufacturing in Australia

The manufacturing process is quite involved. The first step in the process is to cut lacquers using a high quality record cutting lathe, also known as creating an acetate master disc.

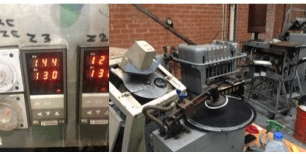

Electroforming is used to make negative metal moulds which are used as a stamper to press numerous copies of the master. The PVC is then put through the extruder. The extruder is controlled by the RKC controller, to ensure the PVC is heated to the correct temperature for extrusion into the mould. Steam is used to heat the PVC, the record is then pressed using one of Zenith Record’s 3 record pressing machines. The cooling of the record is through water. The operator then removes the vinyl record from the press, ready for packaging.

We are pleased to be providing high quality products to support Australian manufacturing. For more information on RKC controllers click here.