1300 737 976

Call us

Live Chat

Call us

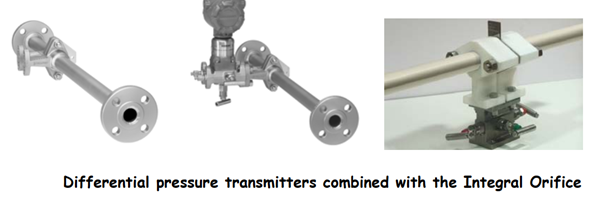

Integral Flow Orifice Assembly is used when Differential Pressure transmitters must be directly mounted on the orifice assembly. This eliminates the cost of installation of differential Pressure Transmitter with impulse piping up to the orifice assembly. This fully integrated flow meter eliminates the need for fittings, tubing, valves, adapters, and mounting brackets, thereby reducing welding and installation time. The transmitter is mounted on the orifice assembly through a Three/ Five-Valve H-type manifold.

The use of an integral orifice flow meter will eliminate the three measurement inaccuracies recorded in small orifice line installations.

• The Integral Orifice honed body reduces ID uncertainty

• By inserting precision bored upstream and downstream sections of the pipe, the velocity profile distortion due to pipe roughness is reduced.

• The self-centering design of the Integral Orifice Plate eliminates plate misalignment.

Improves reliability and maintenance costs

The integral orifice flow meter eliminates impulse lines, reducing leak points by over 50% and decreasing start-up time due to the flexibility of numerous process connection options. The direct mount design minimizes line plugging by eliminating long lines, small-bore ports, and crevices while providing consistently reliable installations.

• Accuracy up to ±0. 5% of volumetric flow rate

• Integral manifold head allows direct mounting of DP transmitters

• Ideal fluid types: liquid, gas, and steam

• Direct mounting capability.

Integral Meter run, due to processing temperature limits of the transmitter, cannot be used for process temperatures above 120 degrees Centigrade.

Pyrosales staff is ready to help you with any inquiry you may have. Our experienced sales engineers will assist you in choosing the correct system for your application.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.