1300 737 976

Call us

Live Chat

Call us

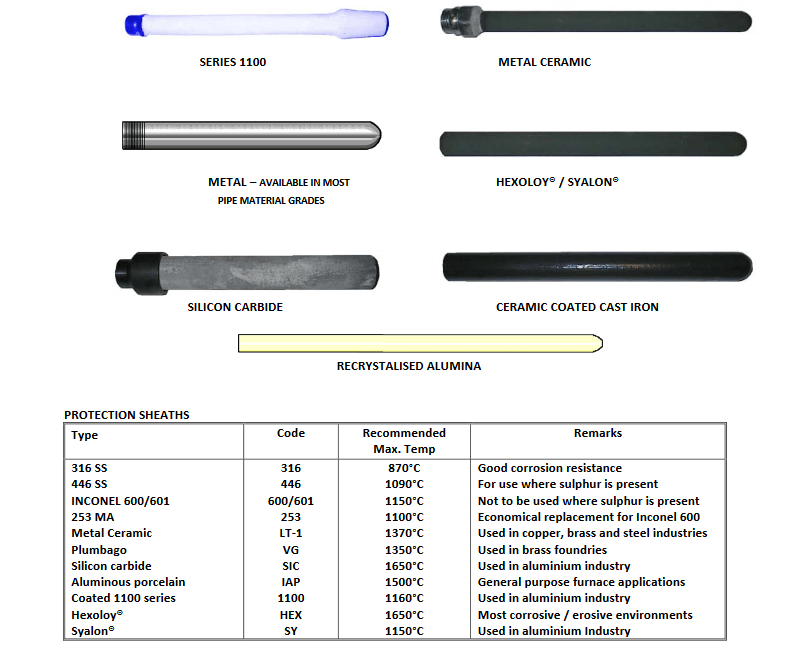

Ceramics and Special Protection Sheaths are a tube covering meant to protect the wiring of the thermocouples that are used in high temperature measurement. The tube covering of the thermocouple is the section exposed to the heat application in the industrial process i.e., such as inside a furnace. The ceramic or protective sheath is not destroyed because of their exceptional heat resistant properties from the compounds they are constructed from.

Pyrosales offer a range of ceramic tubes and insulators to protect your sensor from the harshest environments. The range includes sheaths made from a variety of materials in many sizes to suit your application.

Ceramic sheathes are typically required in high temperature applications up to 2000°C as well as in aggressive environments and where rapid temperature changes occur. A ceramic sheath has one end open and a closed end which acts as a protective sheath to prevent the outer material entering the measurement area. Insulators are designed to protect thermocouple wire and are available in 2 bore, 4 and 6 bore options.

Material selection depends on the application and the temperature. The below table outlines the types of sheathes available, maximum temperature and the applications they are best suited to

Hexoloy SA is made by sintering silicon carbide powder. The process fuses the powder together to create a self-bonded product which is lightweight and extremely hard. Hexoloy SA is highly resistant to corrosion, high temperature, thermal shock, and erosion. Typical applications for Hexoloy SA include heat exchangers, hot gas and liquid exposure, valves and bearings, mechanical seal faces, other mineral and chemical processing equipment components, furnaces and kilns and other high temperature applications.

Metal Ceramic (SLT-1)

Known as the PyroSheath LT-1® is a unique sheath, made with alumina and chromium. It has excellent resistance to oxidising environments over 1250°C. Useful for measuring temperatures of molten metals including, lead, copper, silver, zinc, brass, and tin. Suitable also for corrosive gases at high temperatures, some cement processes, still-mill soaking pits, general foundry practices and oil-fired furnace chambers.

Series 1100 for Molten Zinc, Aluminium & Galvanizing Applications

With an outer laminated exterior and a tough build that resists erosion from molten metals, the Series 1100 remains in superior form after exposure to high temperature. Very little maintenance is required on the Series 1100. Typically, a lower cost item for small aluminium melts.

Sialon

Sialon is an acronym for a combination of materials including, aluminium, silicon oxygen and nitrogen. Sialon is an innovative ceramic tube which offers outstanding performance for managing temperature in smelters and foundries. They are cost effective compared to silicon carbide, cast iron and alumina.

The composition of sialon tubes allows them to have unique properties including toughness, excellent resistance to thermal shock, resistance to corrosion and high strength. They are suitable to a maximum temperature of 1150°C.

Silicon Carbide

Most suitable for use in molten aluminium and reheating, silicon carbide sheaths are highly wear resistant and offer great mechanical properties including high strength and excellent chemical resistance, although care must be taken as it is attacked by water vapour. Silicon carbide does become brittle when aged and is unsuitable for oxidising atmospheres.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.