How accurate are thermocouples?

How accurate are thermocouples?

Thermocouples are manufactured from a pair of wires – made of specific but different metals, thermocouples employ the “Seebeck” or thermoelectric effect to determine temperature differences resulting from voltage measurements between these two electrical conductors. At one end is the “hot / measuring junction” which is connected to the substance needing its temperature measured. The other ends are connected to a “cold / reference junction”, which is a substance with a known and easily measured reference temperature, and here the wires are also connected to copper wires which lead to a meter/display.

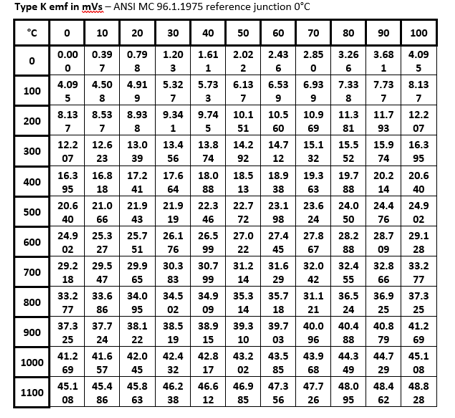

The voltage (millivolt/mV) which is used to determine the temperature differences is not actually generated where the metals join, but instead, the voltage is generated along the entire length of the wires between the hot and cold junctions. The measurement voltage is only accurate if each wire is entirely homogeneous, meaning it has a uniform and consistent composition.

In many industrial settings, thermocouple wires tend to lose homogeneity over time, because of a variety of factors including chemical exposure or mechanical damage (such as a bent wire). Some types of thermocouple metals are also affected by exposure to temperatures more than 200ºC, while others are less easily altered. This is important to note because if a section of the thermocouple circuit is not homogeneous, it can result in a different voltage being generated leading to an overall error in measurement. Consequently, thermocouples require calibration to ensure accurate temperatures are derived.

For thermocouples, calibration specifically refers to the approach of comparing one device to another with a known accuracy. By determining your device’s error margin, you then know how to properly calculate temperatures from the voltages being measured. Generally, calibration takes place in a lab under carefully controlled and maintained conditions, however, field calibration can also be a quick and effective way of checking the quality of your measurements.

Both thermocouples and RTDs are useful sensors for determining process temperature. RTDs provide higher accuracy than thermocouples in their temperature range because platinum is a more stable material than are most thermocouple materials. RTDs also use standard instrumentation wire to connect to the measurement or control equipment, which can reduce the overall installation cost. Thermocouples are generally less expensive than RTDs. They are more durable in high vibration or mechanical shock applications and are usable to higher temperatures. Thermocouples can be made smaller in size than most RTDs and they can be formed to fit a particular application.