Melt Pressure

Melt pressure systems are designed to measure, control and supervise the temperatures and pressures associated with plastics extrusion. Melt pressure control improves the quality and uniformity of extruded products, which reduces potential defects and imperfections, resulting in higher quality products and less wastage. Melt pressure control can also improve the safety of the process. Pressure control provides a means of monitoring and stabilising pressure and reduces the risk of overpressure and consequent damage. Additionally, melt pressure control can extend the life of extruder components by reducing wear caused by inconsistent pressures.

Read more on melt pressure here.

-

Glass Industry Sensors (3)

-

Sanitary Industry Sensors (4)

-

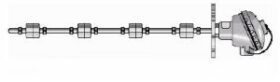

Thermocouples (32)

-

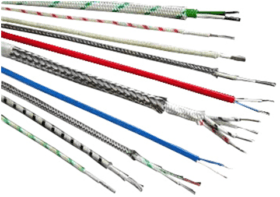

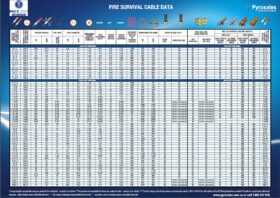

Thermocouple Wire and Cable (22)

-

Resistance Thermometers (16)

-

Thermowells (14)

-

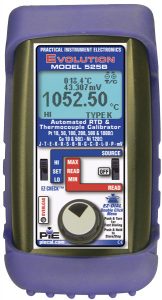

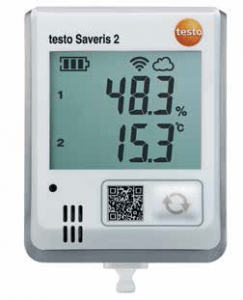

Temperature Controllers and Instruments (110)

-

Accessories (22)

-

Ceramics & Special Protection Sheaths (9)

-

Thermal Imaging (10)

-

Temperature Gauges (5)

-

High Accuracy Temperature Sensors (2)

Our Services

Product Development, Design, Consulting And Manufacture

Pyrosales can design and manufacture custom solutions for precision temperature measurement and process control applications.

Pyrosales frequently repair specialised temperature equipment. We are distributors of the highly trusted RKC® digital temperature controller devices.

Mineral-insulated (MI) cable is a specially constructed cable that can survive a fire. Capable of carrying current at temperatures more than 1000˚C.

We have a large selection of commercial and industrial temperature sensors, gauges, monitoring and control equipment, with superior quality.

We have been assessed and approved by Australian and international quality management systems, standards and guidelines.

To achieve accurate readings from precision temperature sensors, gauges and measuring equipment. We provide accurate calibration and certificates.