1300 737 976

Call us

Live Chat

Call us

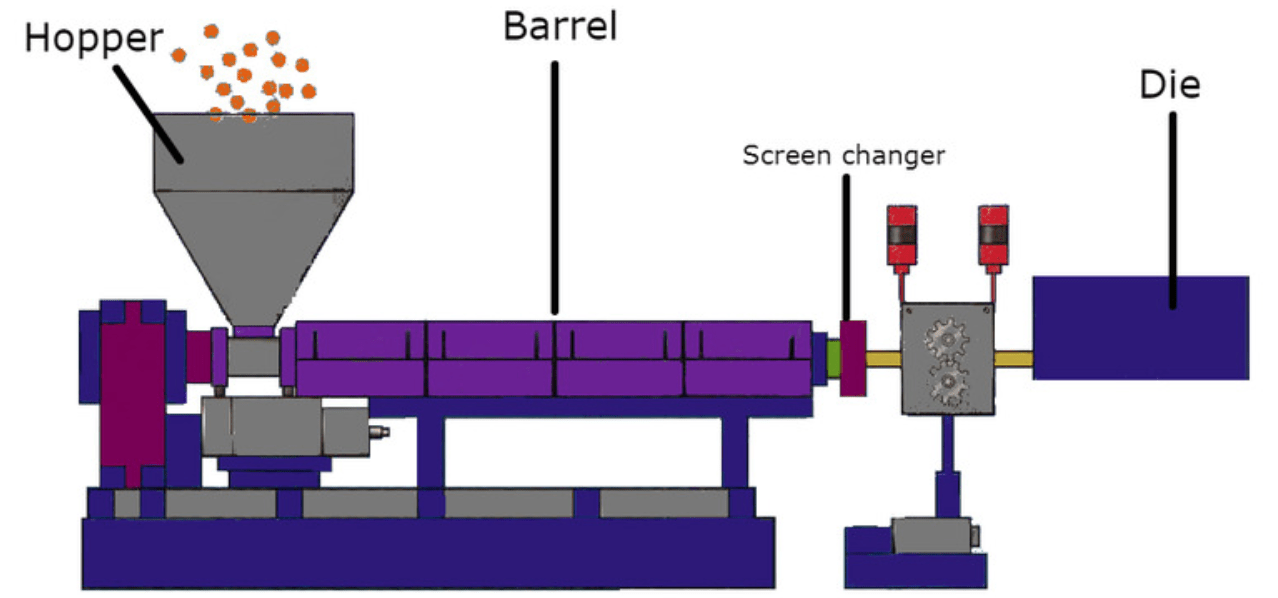

The melt pressure system engineered and supplied by Pyrosales are designed to measure, control, and supervise the temperature and pressure associated with plastic extrusion process. The key components needed to establish a melt pressure control system are transducers, controllers, and indicators.

What is melt pressure extrusion?

Extrusion is a process that involves plastic materials being formed to shape. This is done by first softening the material with heat. Using a drive screw, the material is forced toward and then through the opening, called a die used to shape the plastic melt. Various compounds, colourants and additives can be mixed with the plastic materials as they move along the screw path. The heated materials are shaped by the die and then cooled to retain their shape.

What are melt pressure transducers?

Placing pressure transducers along the machinery ensures increased safety of the extruder and the melt process.

Some application of melt pressure.

Wire Coating: Insulated cable and wire housing. Monitoring pressure in the cross-head die, which is where the wire is coated in the plastic, improves output quality and profits. The need to have a transducer at this process is becoming more important as system are reaching higher speeds, and therefore pressure monitoring becomes vital.

Synthetic Fibers: Fibers used to create end products such as various textiles, brushes, rope, and twine. Placing transducers along the extrusion process helps produce higher quality consistency as well as reducing waste.

Other: Pre-processing for other plastic packaging needs, which can also be used for mixing and compounding.

Rigid Stem Transducer: Interchangeable with competitors , Standard 3.33mV/V, 6 pin connector, Stem (standard), 1% combined error, 80% Output for easy calibration, 400 deg Celsius (750 deg Fahrenheit) rating, standard Inconel tip. Rigid Stem Flex: Offers the same features as the Rigid Stem transducer, with the added benefit of an 450mm stainless steel flexible armour between the housing and the stem. Is used for applications that need more thermal isolation or where installation may be difficult.

Pyrosales’ engineers have over 40 years’ experience producing specialised solutions for any temperature applications. Whether this is an infrared temperature monitoring system or a more traditional contact temperature system, we can design and supply the most effective temperature and process control equipment for furnaces, ovens, kilns, and other extreme heat applications.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.